kuhlmann 软件

评价

产品描述

Control System and Software – oriented to process

The performance of modern CNC controlled milling and engraving systems is essentially defined by the flexibility and quality of the software and control system. KUHLMANN, as a pioneer in this field, can look back on decades of experience in research and development. Our PC based 32 bit multiprocessor path control can operate at high speed with up to 16 precisely positioned axles. 2D and 3D image files can be imported and sent as a DIN/ISO file to the machine. |

| ||||||

Make use of our know-how to cope with your production requirements! | |||||||

Technical data KM3060: | |||||||

| PC control system |

|

| 32 bit CNC multiprocessor path control | |||

| Axis solution |

| mm |

| PIKO interpolation (0,6x10-12m) | ||

| Positioning accuracy |

| mm |

| ± 0,001 | ||

| Number of axles |

|

| Path interpolation up to 16 axes simultaneously | |||

| Number of axles |

|

| SERCOS Interface | |||

| Set changing time |

|

|

| < 100 µs | ||

Design characteristics | |

| Suitable control system and software for any application |

| Close cooperation with software developers, realization of special solutions |

| Powerful state-of-the-art control systems for milling and engraving, suitable for industrial needs |

| Open interfaces, processing according to DIN 66025 |

| Partnership with leading engraving software developers |

| Continuously menu-driven and process-oriented manufacturing sequences |

Options: | ||||||

|

| Control System KM4 |

| Control System andronic KM3060 |

|

|

|

|

|

|

| ||

|

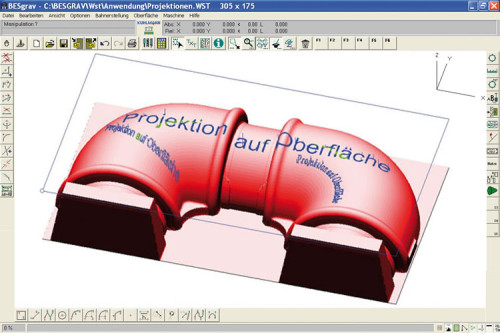

| BESgrav Engraving Software |

| HCAM Engraving and Milling Software |

|

|

|

|

|

|

| ||

|

| Lang Engraving Software LErgoCAD “all-in-one” software |

| Type 3 Engraving Software User-friendly 2D to 3D software |

|

|

|

|

|

|

| ||

|

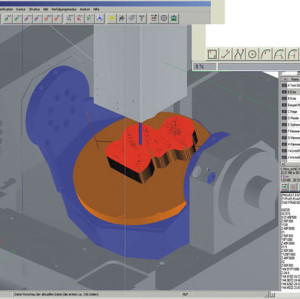

| 3D CAD Software Solid Works Volume modeling CAMWorks Integrated CAM system |

| Scantech Software Fast 3D scanning |

|

|

|

|

|

|

| ||

We will be glad to inform you about further options